Dear DIYer, we are pleased that you are using our products. We have some basic advice for you to help you

with the implementation of your projects.

It is a good idea to make sure you know what you want to use the product for before you start.

An ideal

decision for your project is to use the dimensions of already manufactured products. Low-quantity custom

production is much more expensive than products in stock that were manufactured in the quantity of a hundred

or a thousand pieces.

Is your project for the exterior or interior? What is its purpose? Protection of property, safety, design or

something else?

Think about the finish: will you only protect the material from corrosion or do you want it to look good?

We can deliver our products made of any material as far as custom production is concerned. Their

basic advantages (or disadvantages) are:

Steel

- Most affordable, a wide range of application

- Suitable for welding

- Corrodes, surface requires treatment

- Excellent resistance to corrosion + maintenance free when combined with hot dip galvanization. Zinc is

applied after the sheet has been cut to the final dimension to avoid any disruption of its layer

Galvanized

- Steel material, hot dip galvanized by the manufacturer of the metallurgical material that has been

worked

- Cutting edges are not galvanized

- Not suitable for exterior applications, corrodes

- Suitable for coating or HVAC

Aluminium

- Interesting in terms of the low weight; both structure and price-wise.

- Higher resistance to corrosion but oxidises in time

- Softer – easier processing but higher risk of damage

- Ideal where no mechanical damage can be caused

Stainless

- High resistance to corrosion

- Suitable for welding

- Must be dipped/chemically treated to slow down corrosion when used outdoors

- Premium look, available surface finish such as grinding, brushing, polishing etc.

Corten

- A unique look thanks to the surface corrosion

- Clear varnish recommended to avoid rust from trickling down from the surface in wet conditions.

Our products can also be manufactured in other material such as brass, copper, or even plastic to a limited

extent (prior consultation required).

The products on the e-shop are sold in sheets, profiles in rods, special products in rolls. Pay attention to

the description of the individual items. Custom production is available for atypical formats. Leftover

pieces are not available for sale.

We deliver products in natural look, without surface finish.

Perforated sheets

- Delivered in sheets, the most common formats include 1,000×2,000 mm, 1,250×2,500 mm, 1,500×3,000 mm.

Atypical formats available on request.

- The holes and spacing are stated in millimetres; spacing is measured along axis, from the centre to the

centre of the holes in the same row.

- Bridge = solid sheet between the holes is derivable from the difference between the spacing and the

hole.

- The stock position is cut ‘across the holes’ - the cutting edge is not smooth/solid sheet.

- Sheet thickness suitable for hot dip galvanization starts at 1.5 mm

- The minimum hole for hot dip galvanization has a diameter of 10 mm and an equivalent to the shape,

otherwise the hole will get sealed

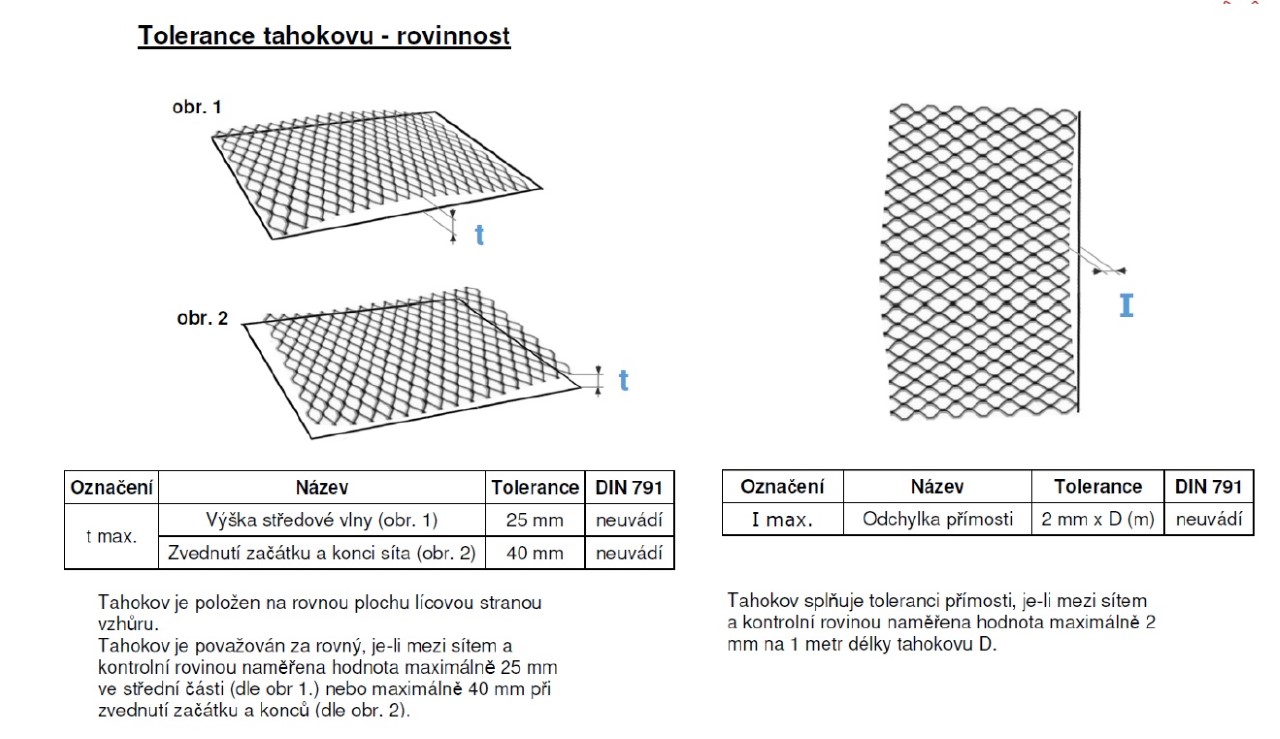

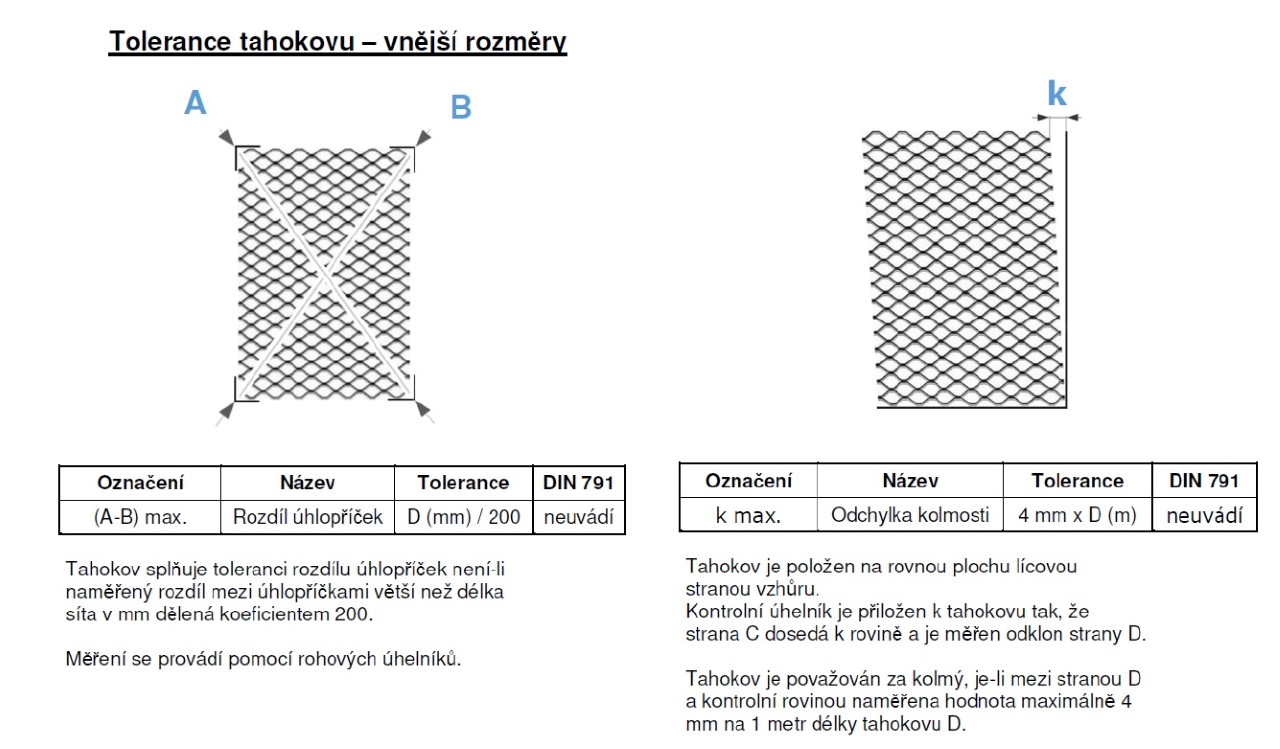

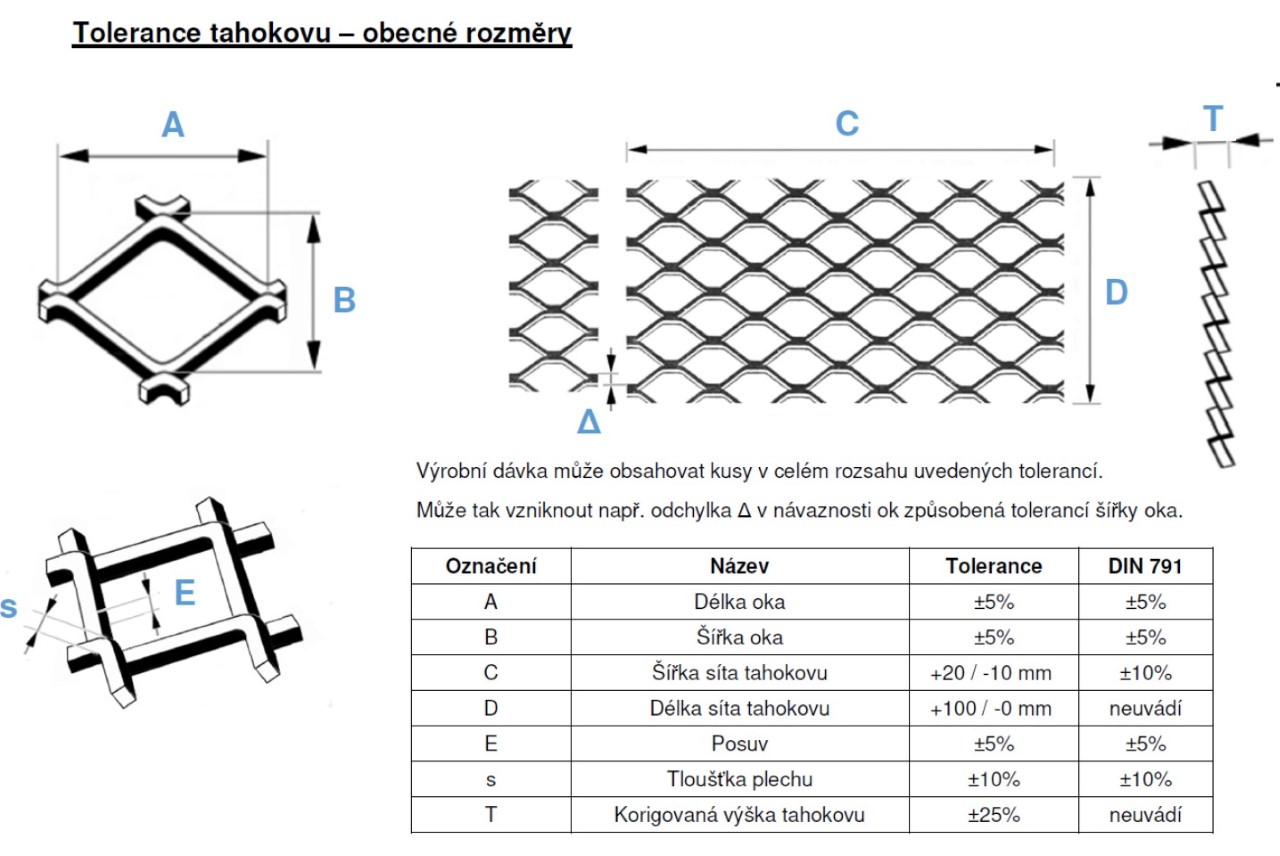

Expanded metal

- Delivered in sheets and smaller thickness in rolls. The most common formats include 1,000×2,000 mm,

1,250×2,500 mm, decorative expan ded metal also in the format of 1,500×2,000 mm / 2,000×1,500 mm.

Atypical formats available on request.

- Four dimensions are required for expanded metal: mesh length, mesh width, bridge width and material

thickness. The mesh length and width are measured along axis – do not measure the internal dimension but

the axial one!

- The mesh length is always parallel with the first sheet dimension!

- The minimum expanded metal suitable for hot dip galvanization is a diamond mesh of 22×12 mm and

equivalent; we recommend larger.

- When doing hot dip galvanization, it is recommended to do expanded metal and frames/structures

separately; otherwise, the structure/expanded metal may be deformed

The most common surface finishes for perforated sheets and expanded metal:

- Powder coating in RAL shades

- Hot dip galvanization

- Zinc plating

- Dipping stainless sheets for the exterior

Grating:

- Custom grating is not much more expensive than grating in stock.

- We manufacture grating starting at one piece

- We offer steel and stainless grating

- We manufacture almost any dimension with high precision

- The grating load capacity is not only determined by the carrying strip, but also by the clear distance

of supports.

- The grating is self-supporting and primarily designed for walking. We also offer road grating.

- The most common carrying strips are 30×2 mm (grating height of 30 mm) and mesh 33×33 mm for pressed

grating / 34×38 mm for welded grating. Expanded metal grating has a mesh of 47×18 mm, 47×13 mm and 62×15

mm.

- The grating is suitable both for the exterior and interior.

- We offer pressed, welded and expanded metal grating.

- Pressed

- Higher variability of production options (grating dimensions, mesh type, non-slip finish)

- Welded

- Suitable for subsequent finish during installation thanks to welding the individual filling

wires into the carrying strips during the production of the grating.

- Stock items are sold at low price

- Expanded metal

- Original look. Suitable for platforms on slopes.

- Steel grating in the stock is crude or hot dip galvanized. Stainless grating is delivered crude, dipped

and polished. Grating can also be delivered treated with thermoplastic powder paint = rubberised.